Why FRP?

When considering the advantages of modern plastics (light weight, ease of handling and installation, high dielectric strength, no corrosion problems), and their disadvantages (cold flow, cold temperature embrittlement, heat distortion, low abrasion resistance, relatively low compressive strength), it becomes obvious that fiberglass reinforced plastic (FRP) provides all the physical advantages and properties while eliminating or materially reducing the disadvantages of the non-reinforced plastics.

FRP’s properties of light weight, ease of handling and installing, high dielectric strength, corrosion resistance with great compressive strength combine to make it the state-of-the-art material for Glas Mesh FRP abrasion control and electrical insulation products. Glas Mesh FRP products will not cold flow under pressure nor become brittle in cold temperatures, will not soften nor distort from heat, and they have excellent abrasion resistant properties.

Glas Mesh products are manufactured by hand lay-up or filament winding from polyester, vinylester or epoxy resins, depending on type of application and temperature requirements. The materials are highly pigmented and gel coated for excellent ultraviolet resistance. Glas Mesh products meet all known industry recommended standards, specifications and properties.

View Our Product Catalog (PDF)

Our Products

Click any product to view more information

Type #240 Roll-On Shields

Glas Mesh FRP Shields and Saddles are non-conductive, pre-shaped 240º or 180º peripheral snap-on pipes, fabricated from a hand laid up ultra-violet protected, salt tolerant, fiberglass reinforced vinylester resin. Pre-selected reinforcements are laminated over specially modified molds to a uniform thickness. Sub-zero temperatures will not affect properties.

-

Used by utilities for electrical isolation and abrasion control of mains and by industry for load distribution, energy conservation, and insulation protection at hangers and supports of over head and pylon-supported pipe mains.

-

Employed for abrasion control on plastic pipe systems and wrapped cables.

-

Substitute for, or use in place of metal saddles where electrical insulation is desirable.

-

Ideal for pipes exposed to corrosive environments.

-

Protects pipe insulation and plastic pipe systems from abrasive wear at overhead hangers and supports.

-

May be banded, cemented or taped into place.

-

Special lengths can be made available.

-

Oversized shields and saddles are used over bridge mains that have had protective tape applied, resulting in an increased outside diameter of the pipe and without damaging the tape.

FRP Type #30, 60, 90, and 120 spacers used with Epoxy Seam Sealer are a cost effective, long term solution to above grade crevice corrosion.

Localized Corrosion pitting (crevice corrosion) is a common problem on exposed steel pipes. Generally the most severe areas of corrosion occur precisely where the pipe contacts its support. This contact point is a natural collection site for moisture. Moisture plus poor drainage creates an ideal corrosive environment. Left unchecked, corrosive pitting will eventually require replacement of the affected pipe. Replacement is always many more times the cost of preventative or corrective maintenance.

FRP TYPE #30, #60 and #90 SPACERS used with Epoxy Seam Sealer are a cost effective, long term solution to above grade crevice corrosion. The Seam Sealer is used to bond and seal the inside surface of the FRP Spacer to the corresponding pipe surface. Once in place the FRP Spacer provides protection on just that small inaccessible section of pipe that needs it most. It is extremely important to use fiberglass reinforced plastic because its high compressive strength enable it to tolerate the point loading that would cause a non-reinforced plastic material to cold flow and fail.

View the Seam Sealer Application Procedure Video (In English and in Spanish)

The FRP Spacers can also be used with Moldable Sealant and Petrolatum Tape when conditions prevent the use of Epoxy Seam Sealer.

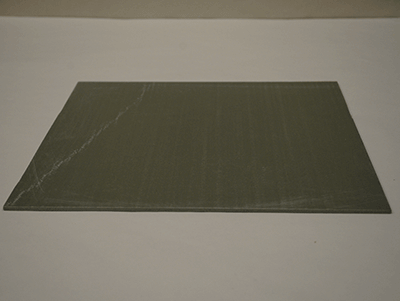

FRP “Flatties”

Flatties are made of a select combination of random glass mat reinforcements saturated with polyester resins combined with suitable fillers.

FRP FLATTIES are made of a select combination of random glass mat reinforcements saturated with polyester resins combined with suitable fillers. These composites are cured and compressed under moderate pressure to form smooth dense laminates. FLATTIES tolerate point loading and are resistant to cold flow. They will not become brittle at cold temperatures. Stocked dimension include 6″ x 12″ and 12″ x 12″ squares or economical larger 3′ x 6′ and 4′ x 8′ sheets. Available thicknesses include 1/16″, 1/8″, 1/4″, 3/8″, 1/2″ and 1″. Will be glad to quote on special dimensions and thicknesses

FRP FLATTIES have numerous applications in the natural gas distribution and transmission and liquid pipeline industries.

-

They eliminate or correct above or below ground metal-to-metal electrical contacts, particularly on underground steel mains.

-

Custom fitting as non-corrosive, non-conductive spacers or shims.

-

A standard product for spacing, isolating or protecting pipes and valves from their supports.

-

Ideal protection for coated tank bottoms.

Type #220-240 Casing Insulator

The Coated U-Bolt is a seamless, vulcanized, polyolefin material that can be applied to all types of u-bolts and eliminates metal-to-metal contact.

The U-BOLT-COTE is a seamless, vulcanized, polyolefin material that can be applied to all types of u-bolts and eliminates metal-to-metal contact. It provides a high abrasive and corrosive resistance on a continuous sheath, eliminating fraying and unraveling. It comes in a variety of sizes and can easily be applied to all makes and sizes of u-bolts.

-

It is excellent for eliminating corrosion problems on piping in refineries, chemical plants, paper mills, offshore platforms, rigs and the shipping industry.

-

Virtually unaffected by heat, ultra-violet rays, vibration, electrolysis, sandblasting and any other rigors specific to industrial and marine environments.

-

The U-BOLT-COTE is excellent for use on plastic, FRP or glass-lined pipe for shock absorption.

-

The U-BOLT-COTE also will help reduce vibration and noise levels.

Non-Conductive Rollers are used in lieu of FRP Shields with any thin barrier coating. The urethane based rollers are used as a direct replacement for cast iron rolls.

Non Conductive pipe rollers prevent the passing of current from the pipeline to bridge structure and rebars. As a direct replacement for cast iron roll, non-conductive pipe rollers are made of the highest specification polyurethane compound which is cast around an integral steel sleeve to form a full length bearing for the axle. They can be used in conjunction with the FRP Type # 240 Roll-On Shields™.

Maintain same support strength of pipe hanger system.

-

Eliminate chafing and rusting pipe caused by iron rolls.

-

Eliminate electrical grounding of the pipeline to the bridge.

-

Eliminate insulating joints at each end of the bridge, and include the suspended line as part of the cathodically protected pipeline maintaining continuity of cathodic protection.

-

Absorb vibration from traffic or other sources, saving wear and tear on pipe hanger parts.

FRP and Co-Polymer Half Rounds